Process: automatic feeding - automatic detection and identification of front and back features - automatic classification - automatic counting and stacking - automatic paper separation and card separation - automatic paper cutting

1、Main parameters and function description of equipment:

1. Automatic plate separation before packaging to prevent mixing; Automatic counting and automatic folding; Automatic lifting table: manual loading and unloading;

2. The printed characters (black oil, green oil, gray oil, white oil, butter, etc.), two-dimensional code, material number, cycle, batch number can be recognized on both sides; Etching characters (can be recognized by naked eyes), hand drawn fork plate (red, black, white oil pen)

3. The machine worry system automatically generates inspection records, lists data tables by material number, product name, cycle, LOT, quantity and date, and generates barcode labels and printers by package according to the set SET/package quantity. The machine is designed to reserve the interface for automatic packing;

4. Precision: 99% detection, no unqualified products are judged as qualified products, and qualified products are judged as unqualified products ≤ 0.2%

5. The working size of the machine shall meet the following requirements: minimum 80 * 80MM~maximum 450 * 450MM

6. The working efficiency is 1800~2400 pieces/hour (depending on the size of PCB board and the number of feeding channels, and the feeding channels 4-2-1 are optional)

7. Power supply of automatic feeding section: 220V 50HZ; Power: 2.2KW; Rated air pressure: 50L/min (5~8kg/cm2)

Power supply of automatic identification section: 220V 50HZ; Power: 8.8KW; Rated air pressure: 100L/min (5~8kg/cm2)

Power supply of automatic classification section: 220V 50HZ; Power: 7.5KW

Power supply of automatic stacking section: 220V 50HZ; Power: 5KW; Rated air pressure: 100L/min (5~8kg * 2 circuits/cm2)

Power supply of automatic cutting section: 220V 50HZ; Power: 2.2KW;

Automatic strap, weighing: 220V 50HZ; Power: 5KW; Rated air pressure: 100L/min

Automatic body fitted packaging, automatic laser cutting: 380V 50HZ; Power: 15KW; Rated air pressure: 100L/min

8. Temperature and humidity requirements: temperature 10~35, humidity 35~80&, standard PCB industry workshop

9. Equipment size: 9830 * 2153 * 1835mm Equipment weight: 1.8T

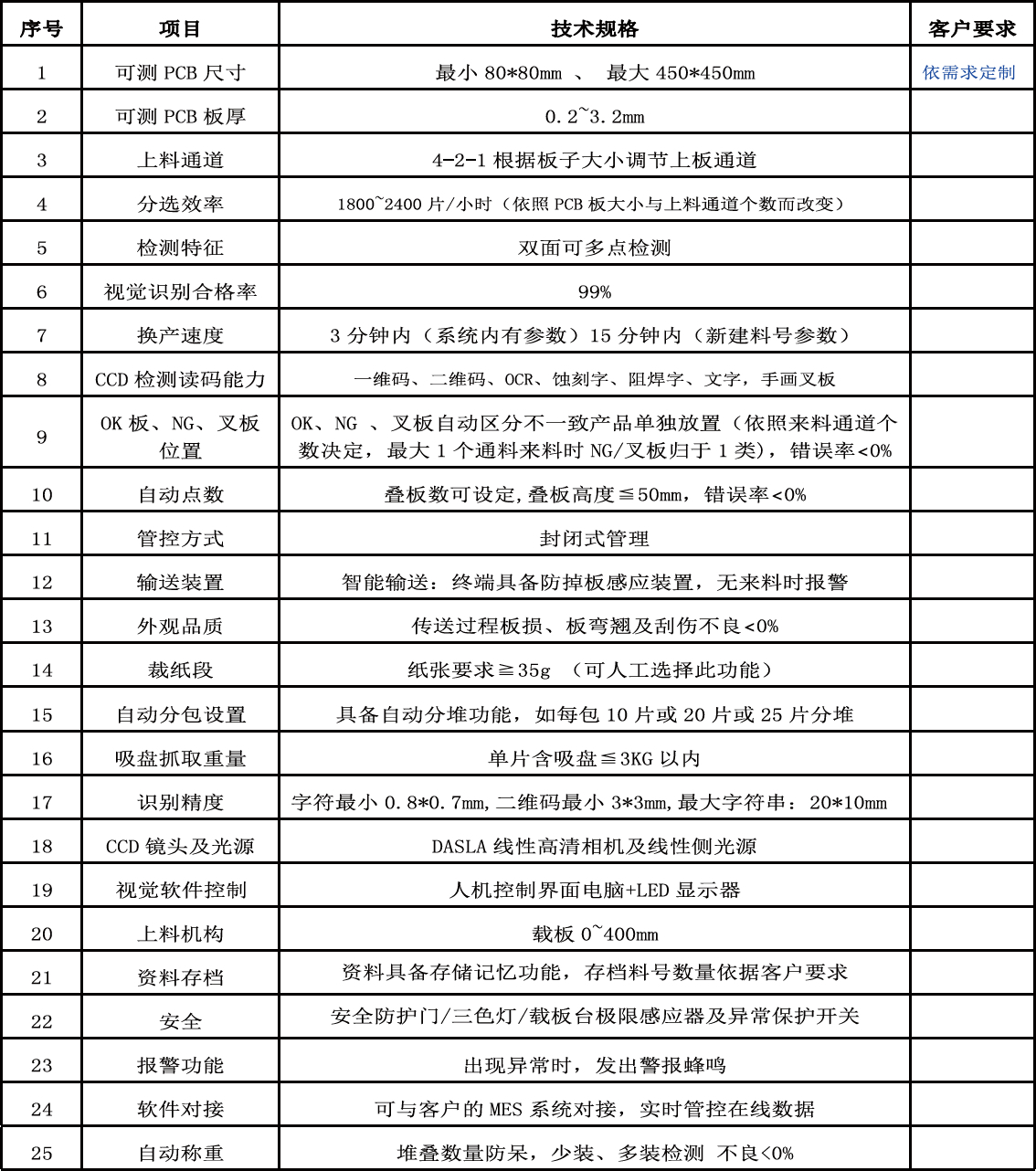

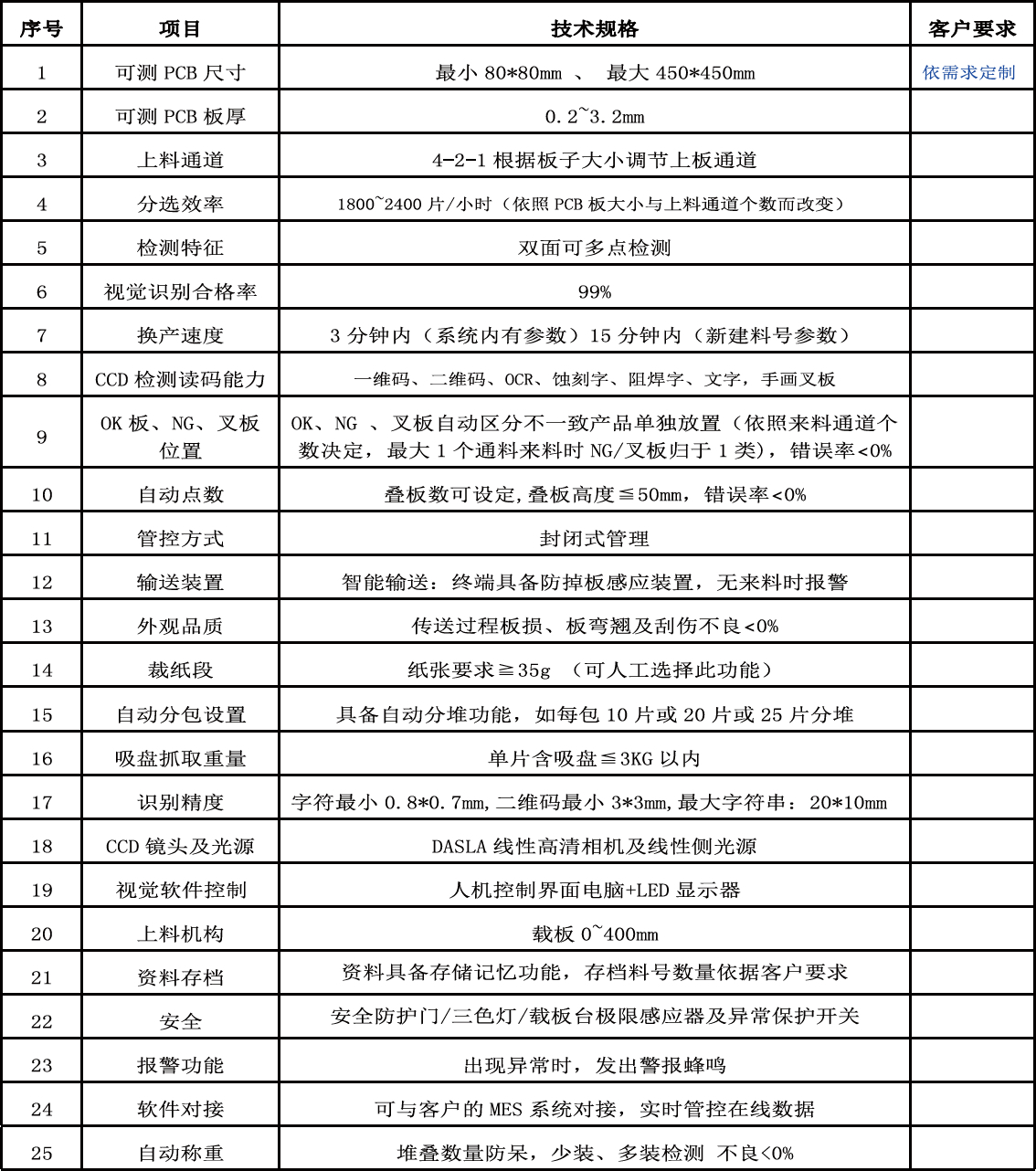

2、 Process technical specification data: